S.P.C. – Spectacular Products Continue

By Will Swagel

First published in the 2013 Sitka Harbor Guide

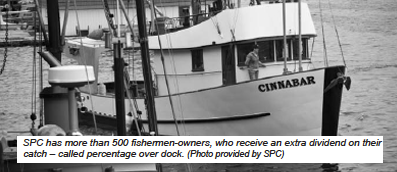

Fishermen are a famously independent lot who sometimes get accused of letting their independence get in the way of their own long-term economic interests. Well, the more than 500 fishermen-owners of Seafood Producers Cooperative (S.P.C.) can tell their accusers a story that shoots that reputation right down.

It’s a story that goes all the way back to the 1940’s, picks up in Sitka in the 1980’s and continues big time today. The fishermen-owners of S.P.C. produce eight million lbs. of catch annually, netting $44 million in gross sales revenues. With buying stations up and down the West Coast, S.P.C today is the oldest, largest and most successful fishermen’s cooperative in North America.

It’s a story that goes all the way back to the 1940’s, picks up in Sitka in the 1980’s and continues big time today. The fishermen-owners of S.P.C. produce eight million lbs. of catch annually, netting $44 million in gross sales revenues. With buying stations up and down the West Coast, S.P.C today is the oldest, largest and most successful fishermen’s cooperative in North America.

“The fishermen deliver their catch to their own company,” said S.P.C Sitka Plant Manager Craig Shoemaker of the Coop’s business plan. “We process the fish and market it for the fishermen, returning dividends to the fishermen, above and beyond what they would normally get if they sold their catch for cash.”

Shoemaker explained, for example, that halibut might be fetching $6 per pound at the dock. After the product is sold, S.P.C fishermen might get a 5 percent dividend – 30 cents extra per pound.

“We call it percentage over dock,” Shoemaker said. The rest of us might call it a chunk of change.

Halibut Livers and Vitamin A

Halibut Liver Oil Producers Cooperative began in 1944 as a partnership between the Deep Sea Fishermen’s Union, the Seattle Boat Owners Association and the Lyle Branchflower Company. Branchflower was a producer of Vitamin A made from fish liver oil.

Because of federal anti-trust action and the post-war introduction of synthetic vitamins, the cooperative – then called Halibut Producers Cooperative – changed its focus to become a food producing co-op. The company expanded, eventually purchasing its own processing plant in Seward, Alaska (formerly owned by Icicle Seafoods). Unfortunately, the Seward plant – along with the rest of that town’s waterfront –slid into Resurrection Bay during the devastating Good Friday earthquake in 1964.

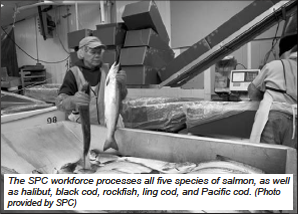

In 1978, H.P.C. began construction on a new processing facility in Sitka. Product lines continued to evolve and become more diverse. In 1984 the company name was changed to Seafood Producers Cooperative. Today, the Sitka plant processes all five species of salmon, as well as halibut, black cod, rockfish, ling cod, and Pacific cod.

At Home in Sitka

Craig Shoemaker was raised in Kotzebue and worked at a number of seafood plants in Alaska. He came to Sitka on New Year’s in 1982 to assist in the development of the inventory control and shipping department. He would eventually become plant manager, the position he still holds. S.P.C. employs 36 resident Sitkans on a year-round basis, and hires an additional 85 employees for the peak summer season.

During the winter months S.P.C. processes king salmon, rockfish and bait herring. The 2013 longline season for halibut, black cod and rockfish was scheduled to begin March 23, and to be followed by the roe herring fishery. During this period staffing will increase to approximately 70 employees – working round the clock in two 12-hour shifts.

Shoemaker paused a moment to comment on the magic of early spring in Sitka: “You’re coming out of winter and the early spring days are getting longer,” he said. “You’re looking at the birds and they’re really hungry. Longline fishing begins, large schools of herring are moving into the area with the sea lions and the whales in pursuit; the table is set and the feast begins.”

Members continue to troll for spring king salmon through May and June. July 1st marks the beginning of the general troll season which continues though the third week in September. Shoemaker said that work is slowing down at the plant by the beginning of October.

The size of the S.P.C. workforce mirrors the progression of the fisheries. Thirty five workers are brought in for herring. In June another 40 or more are brought in for the salmon season.

“In July and August, fishermen are real busy harvesting, like farmers,” Shoemaker said. “June 25 to September 10, that’s the big time of the year. By mid-September things are beginning to slow down a bit.”

Hairnets, Boots & Gloves

A friend of mine from San Francisco used to wax poetic about the three summers he spent in Kodiak working in plants processing fish on what he affectionately called “the slime line.”

Until the 1990’s, Alaska fish processing jobs were prized by American college students, who could work long hours and earn much more than they could in most jobs in the Lower 48. And – like my friend – they were also attracted by the prospect of an adventure in Alaska.

Filipinos in Alaska have had a long history with fish plants, with many workers making Sitka their home. Processing jobs have also lured Latin Americans.

Until recently, scores of college students from Poland and other Eastern European countries were allowed to work summers in the U.S. under the J-1 visa cultural exchange program, which was started in the mid-60s.

“The Alaska seafood processing industry enjoyed having those student employees for many seasons,” Shoemaker said. “But a year ago, the State Department declassified seafood processing for that program, so now we are moving more towards a domestic workforce.”

Shoemaker said he hopes the recent high unemployment rates in the Lower 48 might draw U.S. college students back to Alaska again. And if the backpacking visitors to Sitka each summer are any indication, an Alaskan summer hasn’t lost any of its allure for the young.

All Along the Coast

The scene outside the S.P.C plant is a busy one. Fish are unloaded from boats, while line workers labor to keep up with the flow. Ice is everywhere. Hundreds of squawking gulls – and often eagles – take up positions in and over the channel to catch any errant morsels. The plant is attractive, well maintained and smells like fresh fish.

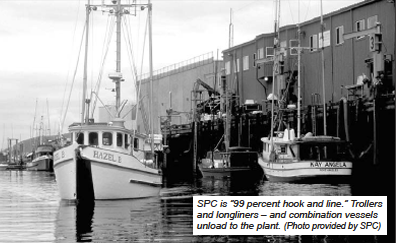

S.P.C. continues to grow. While Shoemaker said the company is “99 percent hook-and-line,” made up of salmon and longline fishermen, there are also members involved in the gillnet fishery. A few years ago, salmon trollers in California asked S.P.C. to expand its range of operations into their fishery. S.P.C.’s presence in the California hook-and-line fisheries has now evolved to include jig-caught albacore tuna.

S.P.C. continues to grow. While Shoemaker said the company is “99 percent hook-and-line,” made up of salmon and longline fishermen, there are also members involved in the gillnet fishery. A few years ago, salmon trollers in California asked S.P.C. to expand its range of operations into their fishery. S.P.C.’s presence in the California hook-and-line fisheries has now evolved to include jig-caught albacore tuna.

S.P.C.’s headquarters are located in Bellingham, Washington. The Sitka plant is the Cooperative’s only wholly-owned facility. The Co-op has outports in California, Oregon, Washington and Alaska. They have processing agreements with companies in Ketchikan, Craig, Yakutat, Seward, Kodiak, King Cove and Dutch Harbor. In addition, they also run four fish-buying tenders that provide member service in the regional southeast Alaska fishing grounds.

“There are about 17 ports which provide an opportunity for members to deliver to their company from California to Dutch Harbor.” Shoemaker said. “We contract with these other companies to receive, process, freeze and ship on our behalf, to provide these services for our member-owners.”

Arrangements like this could be seen as allowing the independent fishermen to be even more independent. But it goes beyond that.

“Our member-owners have a common belief in high-quality products – and with the work they put in to achieve that, they feel they should be rewarded,” said Shoemaker. “They feel their catch is usually worth more than what they would receive as a dock price.”

Visit Seafood Producers Cooperative online at spcsales.com.